Search

3PL Warehouse Relocation

3PL Warehouse Relocation

Cosmetics and fragrance relocation project to a new 3PL provider with greater capability, scale, cost control focus and willingness to go the extra mile to achieve higher service levels.

3PL Relocation Project

This involved going to market and releasing a tender to suitable and capable 3PL operators who could support a complex business as a 3PL outsourced operation. The selection process was quite detailed and involved interviews, site visits and discussions with existing clients to understand the true capability and experience with new prospective 3PL operators.

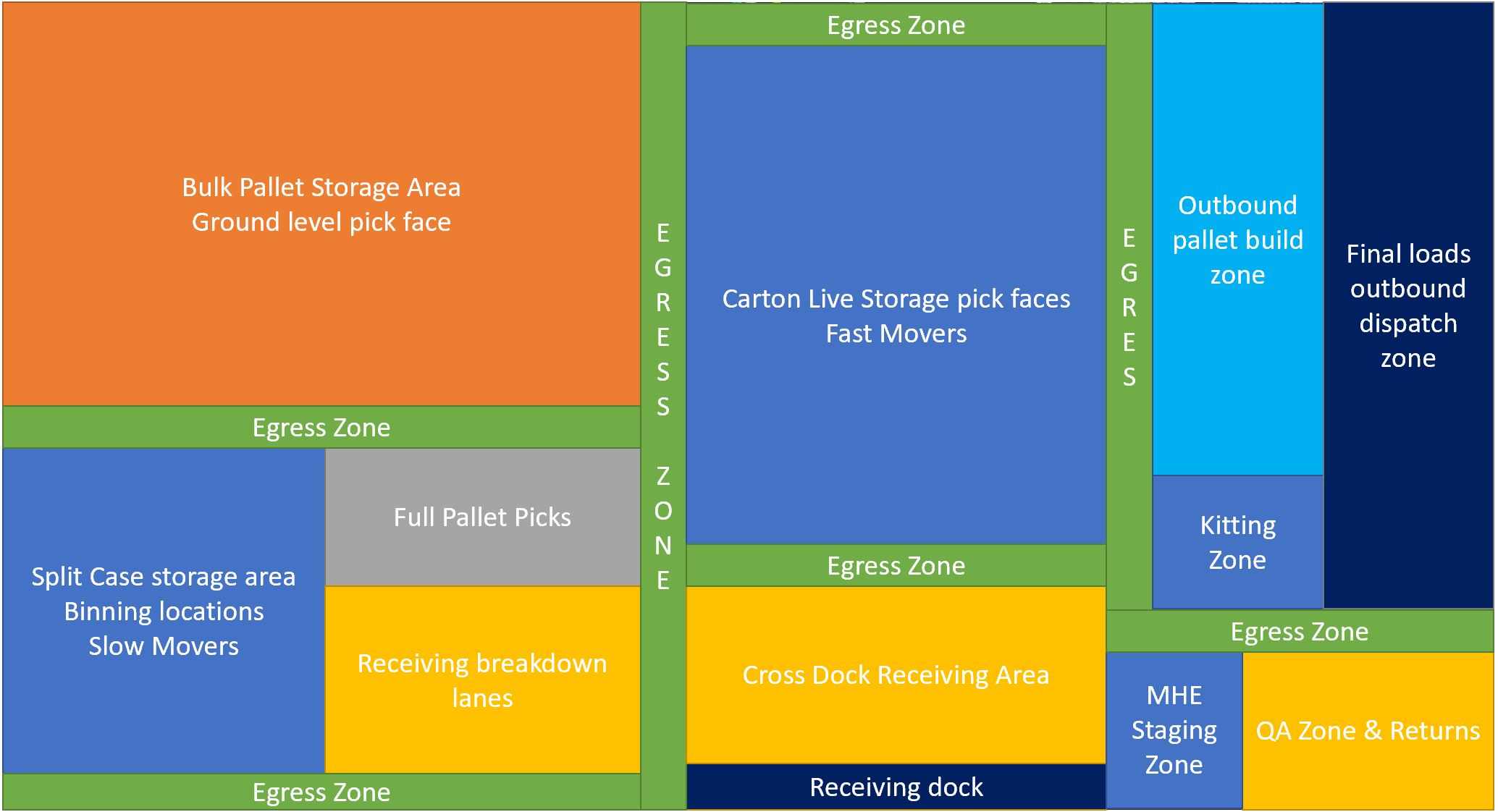

The next phase involved the development of detailed client requirements along with a transition plan which was project managed from scope to final golive. This process involved numerous stakeholders from within the business, technology SME's and warehouse specialists that focussed on creating the right layout within the 3PL operation.

Core Problem

- Current 3PL contract was not balanced, creating a large cost exposure to this client.

- Existing 3PL performance was not delivering promised service levels and order response times.

- Existing 3PL facilities were limiting client's growth and impacting on future growth potential.

- The layout of the existing 3PL caused lengthy cycle time delays in releasing inventory to market

Problem resolution

- Completed and extensive review of 3PL facilities, contracts, and SLA's to understand the core issues.

- Site constraints along with contract limitations paved the way for a new 3PL RFP.

- Vendor assessment and selection completed within 3 weeks

- Warehouse relocation project commenced involving the move of all inventory to the new 3PL.

- ERP systems were interfaced with new 3PL provider to also support EDI order management.

- New 3PL layout implemented within 3 weeks prior to go live.

- Staged implementation from old to new 3PL within 6 weeks.